Services

Faycon Construction have bridged the gap by developing a building system that brings the benefits of reduced construction time and costs.

Faycon is one of the first few construction company that uses industrial building systems (IBS)

Faycon is one of the first few construction companies in Malaysia to use Industrialised Building System (IBS).

IBS can be defined as a construction technique whereby structural components are manufactured in a controlled environment, on-site or off-site, transported and assembled into a structure with minimal side works.

The technology has been around for over 10 years, but it was only used in big construction projects such as the building of factories, warehouses, etc., and never in the private sectors due to high customisation cost.

At Faycon, we will help to construct homes using quality construction technique while saving on cost and construction time.

Our Technology

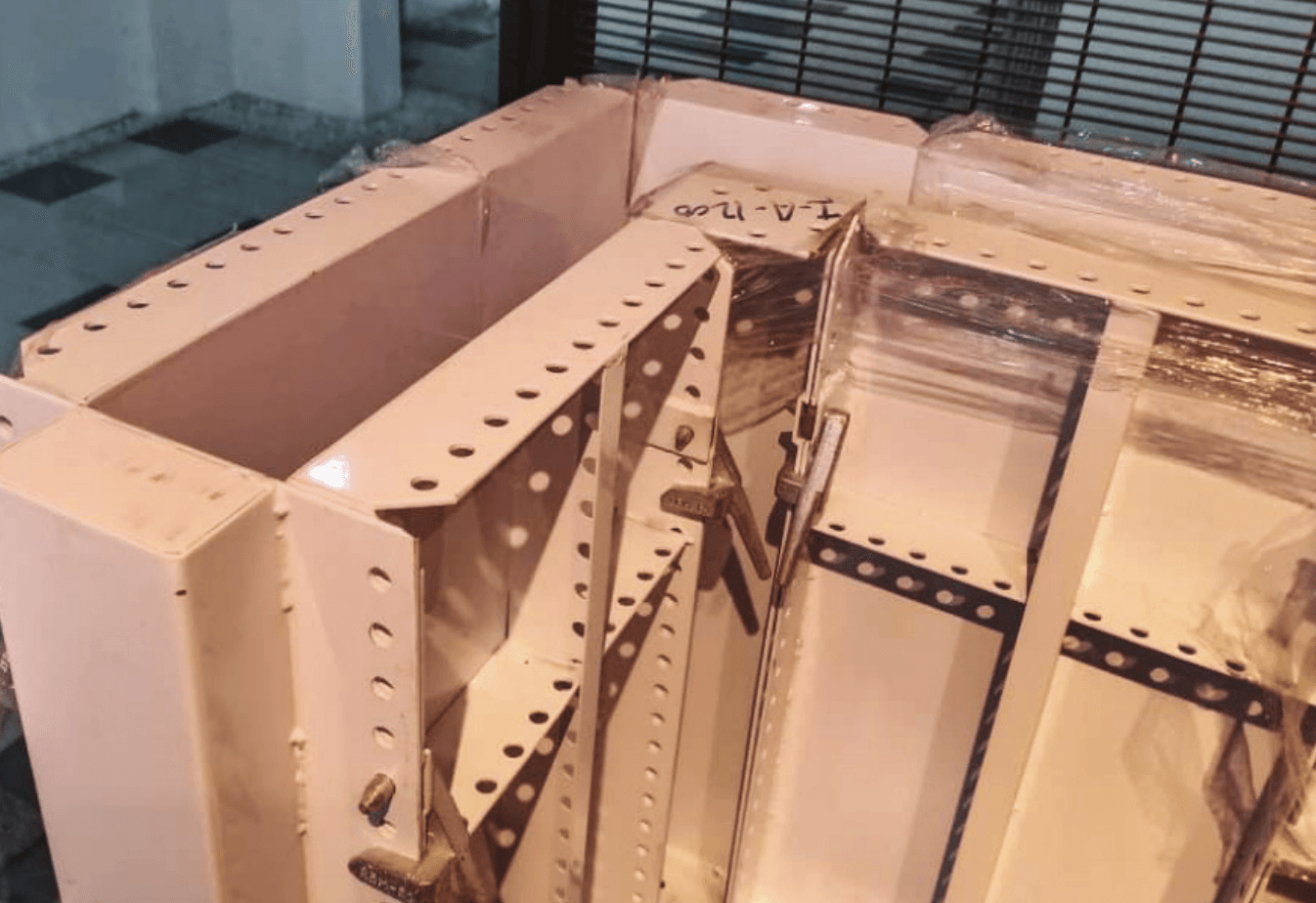

Cast In-Situ Formwork

Faycon uses a flexible, cast-in-situ formwork system that allows skilled workers to assemble the shape of your house based on the exact design size before pouring in high-grade concrete to complete the structure of your house.

Our formwork is made out of strong mild steel with a size of 60mm by 120mm to provide a firm structure for straighter walls. It is manufactured using laser cut technology with jigsaw joints which enables our skilled workers to quickly install the formworks and reduce construction time.

At first glance, one may wonder how a fixed-sized formwork can be used for a custom-sized house. For Faycon, the secret lies in the very use of an adjustable piece of formwork which can be used flexibly to build the exact dimensions of your house.

Slide title

- Strong mild steel

- Flexible end panels

- Quick installation

Button

Strong mild steel formwork provides straighter walls

Flexible end panels to suit any sizes

Quick installation for reduced construction time

01

Faycon has chosen Raft Foundation (300mm thick with 2 layers of BRC A10) for a couple of reasons.

02

One, it reduces construction time by being able to pre-install reinforcement column bars and also all services such as sewerage, main electrical cable and fresh water supply. Two, it creates a more sturdy structure that reduces wall cracks upon ground movement.

03

The shape of the walls are lined up with Fayon steel form, along with a layer of wire mesh in between that serves as reinforcement of the columns and beams.

04

During this time, the M&E outlets and trunking system will also be installed before concreting.

05

Lysaght Bondek® is our preferred decking & ceiling system that provides efficiency and speed of construction.

06

Upon dismantling of steel form, inspection will be carried out to ensure structure is robust.

07

Water leakage is a major enemy to any building. Water proofing works is thoroughly done to susceptible areas to ensure a longer lasting building.

08

Layer of skim coat will be applied before commencing paint.

What we do

- Pre-Cast Concrete Framing, Panel and Box Systems

Faycon offers pre-cast framing, panel and box systems using concrete, which is long-lasting and a cost-saving solution.

- Steel Formwork Systems

Normally used for circular or curved structures such as tunnels, making it stronger and more durable than timber formwork.

- Steel Framing Systems

A fast structural system designated to build panels and continuous walls, low-rise buildings, and high separating walls.

- Prefabricated Timber Framing Systems

A cost-friendly solution as it is made up of multiple wooden modules, which are prefabricated and then delivered to building sites.

- Block Work Systems

A construction technique using large concrete or cement blocks that are larger than a normal clay brick but have a hollow centre, making it lighter and easier to work with.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Have a project in mind?

FOR QUOTATIONS, INQUIRIES OR COMMENDATIONS, PLEASE CONTACT:

Mobile: +6010-226 8714

Email: info@faycon.com.my

HEAD OFFICE ADDRESS

B1-11-02,

Dataran Niaga Sungai Besi,

Midfields Square West,

Jalan 11/108c, 57100 Kuala Lumpur

WE'D LIKE TO HEAR FROM YOU

CONTACT US

We will get back to you as soon as possible.

Please try again later.

Faycon Construction is Malaysia's pioneering adopter of Industrial Building Systems (IBS) to streamline construction speed, costs and quality for both industrial and residential structures.

QUICK LINKS

CONTACT

B1-11-02,

Dataran Niaga Sungai Besi,

Midfields Square West,

Jalan 11/108c, 57100 Kuala Lumpur

OPERATING HOURS

Mon - Fri 10am - 7pm

Sat - Sun 10am - 6pm

Faycon Construction. All Rights Reserved. Website Designed by Heroes Of Digital.